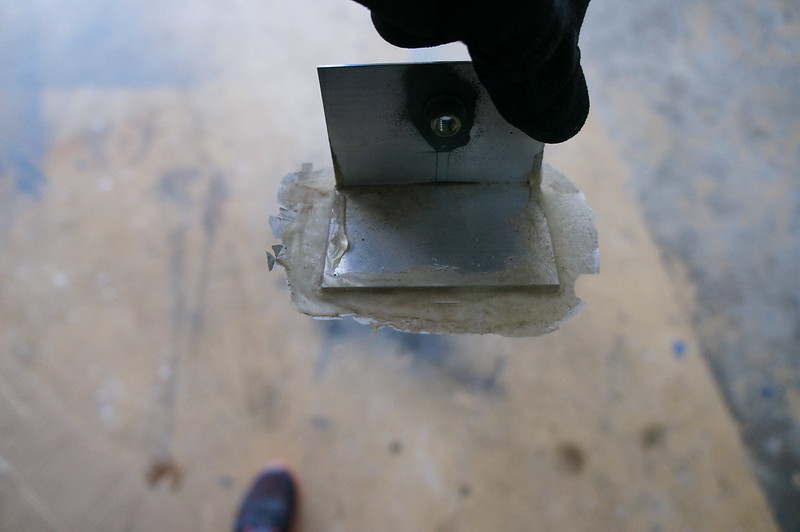

The roof lights are mounted. I ended up using CA (super) glue to bond them. The waterproof silicone casing is incompatible with most adhesives.

I installed some 6x9 Speakers in the over-cab cabinet.

http://amzn.to/1WYnnWT

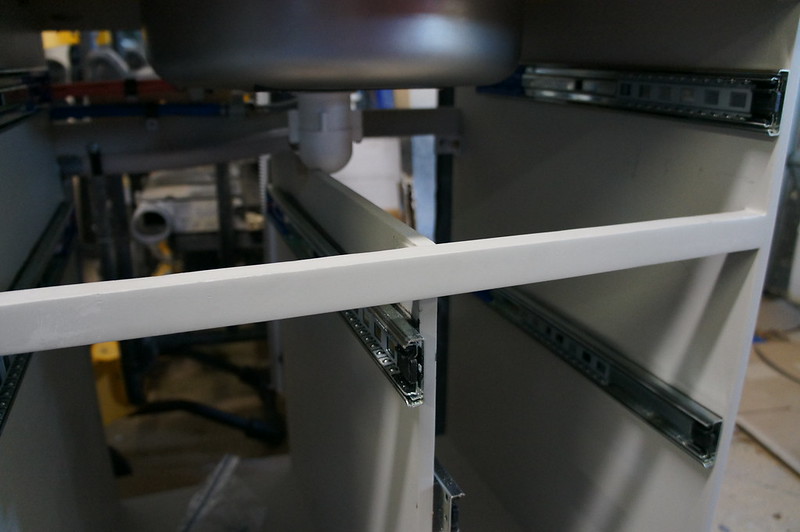

The Galley Drawers have been made and mounted.

The Sink and Cooktop are screwed/glued down and sealed.

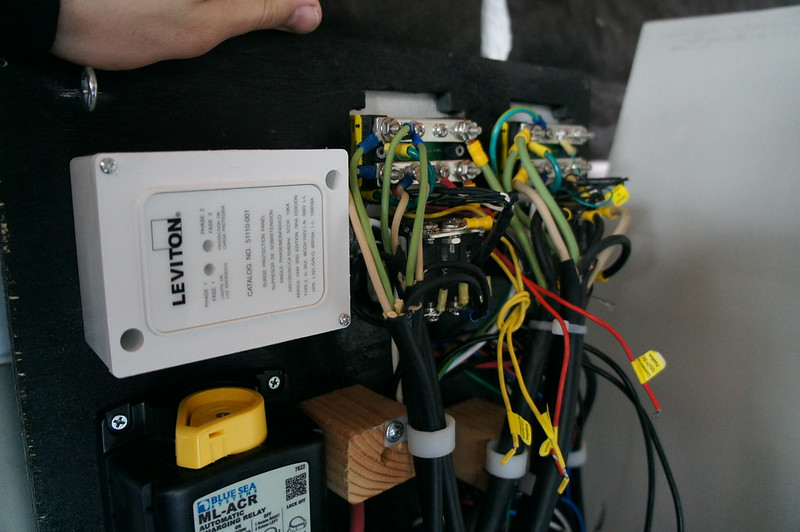

I did a final fit check of the fridge and finalized the wiring in the galley. There was enough room to install ¾” foam insulation on the sides and ½” on the top of the fridge.