It will be 101F and over 110F with the heat index today shortly. I am done with this state. To freaking hot. Must escape... Must…complete…van… The madness is setting in, I need to get back on the road, it’s been too long. It's winter in Australia right now. Just an FYI.

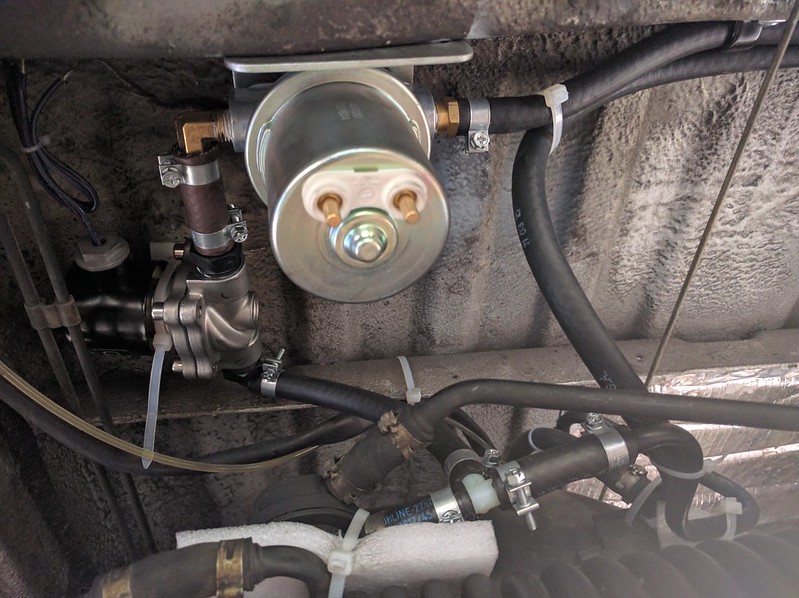

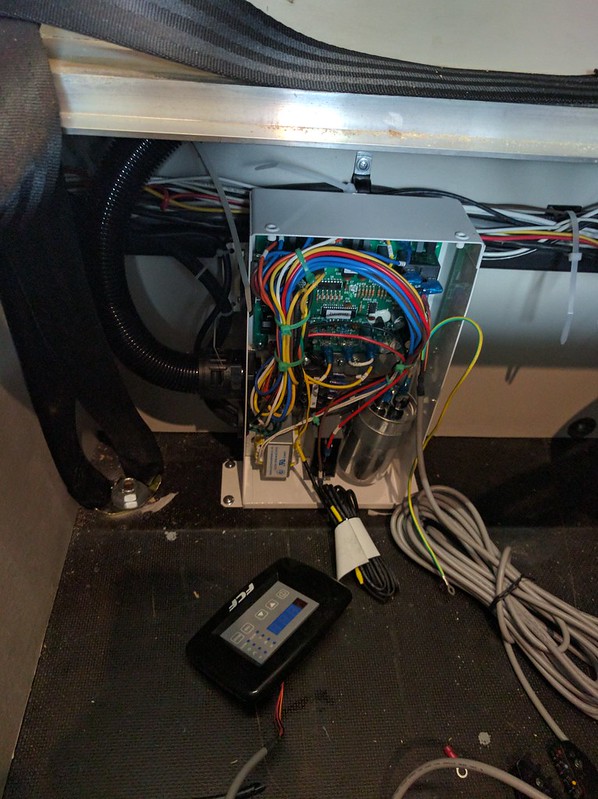

The fix for the AC system overheating was to install a larger pump. The one I used is a Bosch Mustang intercooler pump. The difference in size is hopefully a good indicator of its performance.

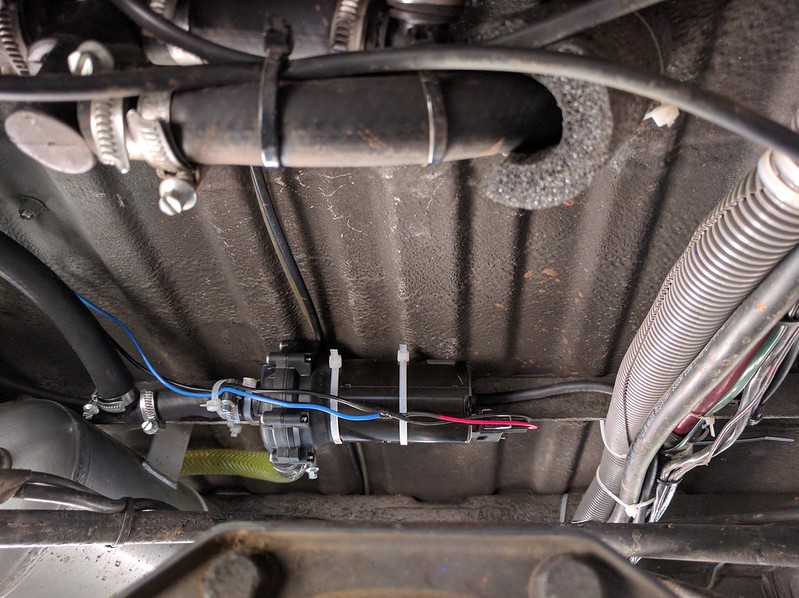

I ended up mounting it above the axle.

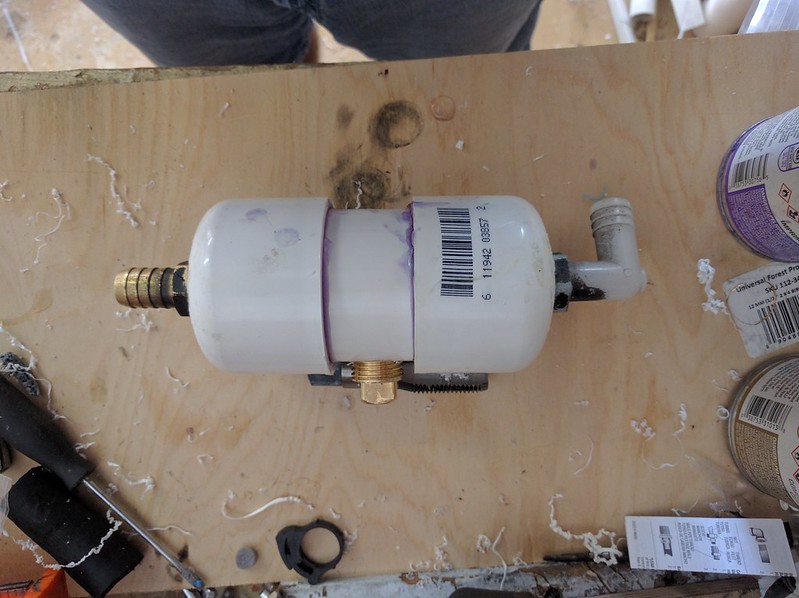

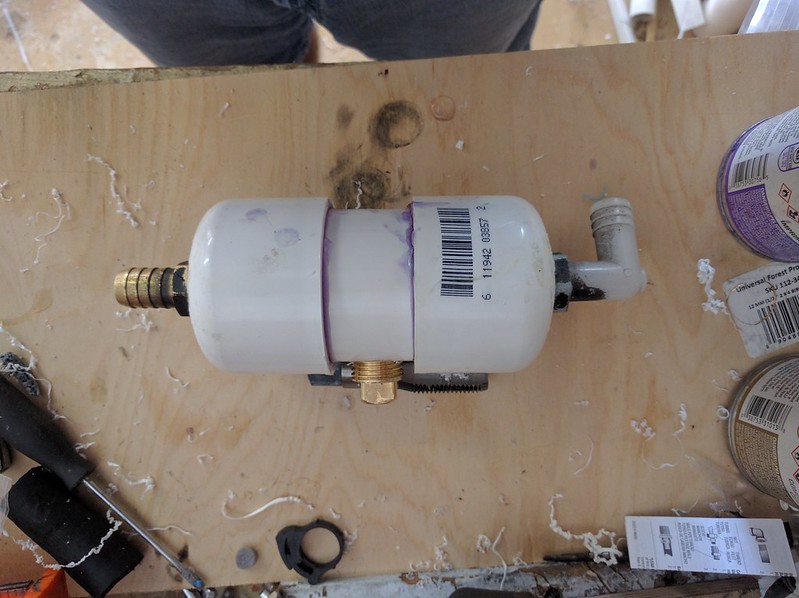

I got tired of trying to bleed the water loop of air. I made up a quick tank using some barbed fittings and 2” PVC end caps.

The unit works correctly now. After 3 hours no errors or safety shutdowns occurred. The cooling loops stays pretty steady at about 15F above ambient on the cold side and 20F above ambient on the hot side. Ideally I would install a larger radiator, but I just don’t have the space for it.

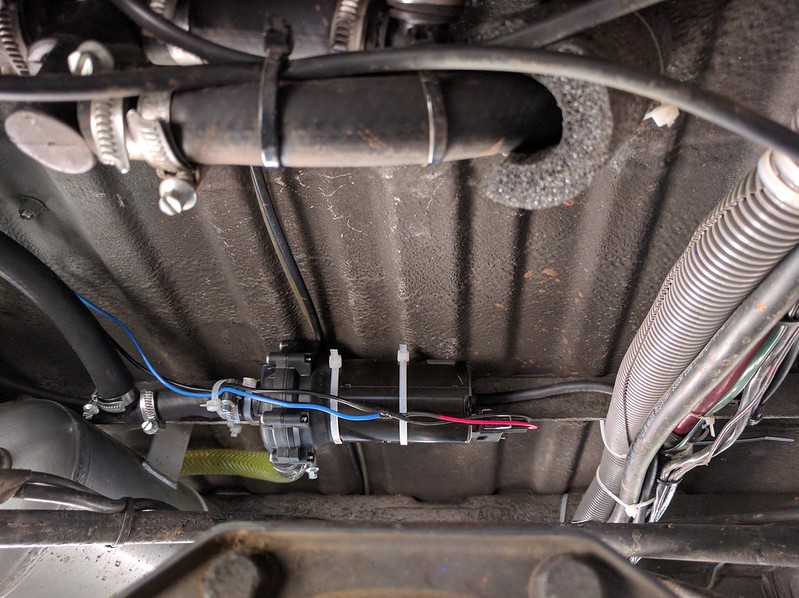

Here is a shot of the condensate drain. It takes about 30-45 minutes or so before the humidity bottoms out and the unit starts to cool in earnest.

The D5 exhaust interfered with the radiator mounting, so I shortened and rerouted the exhaust straight downward.

While I had the fridge out I also added a 120V outlet to the aft face of the galley. Jen wanted it for using a waffle maker or other kitchen appliance.

The auxiliary fuel tank is leak free. I pressure tested at about 1.5PSI and no bubbles. My welding has improved enough, that I could do the tank a second time and have a handful of leaks. In the meanwhile I have been accumulating hardware and fittings for the tank install.

I decided on the Carter P4070 for a transfer pump. It is rated at 72GPH and ~5psi. After some testing I can confirm that it is reversible. I am not sure if it will affect its longevity. However, given the limited usage it will see, I doubt it is a concern.

Because this type of pump will readily pass fuel when turned off, I needed a valve to prevent siphoning. I choose a 1/2NPT solenoid valve with Viton diaphragm. I will be using the vent fittings already on the tank for the return/vent. For the feed I am considering a stainless blind fitting. This one is designed for use with Webasto heaters and has a 1/4NPT port. Unlike the Espar pickup, this unit has a non-threaded section of the body and an O-ring which compresses to seal the area around the threads. I will be using sealant regardless though. I am still waiting on insulation for the tank, and a few fittings before starting the installation.

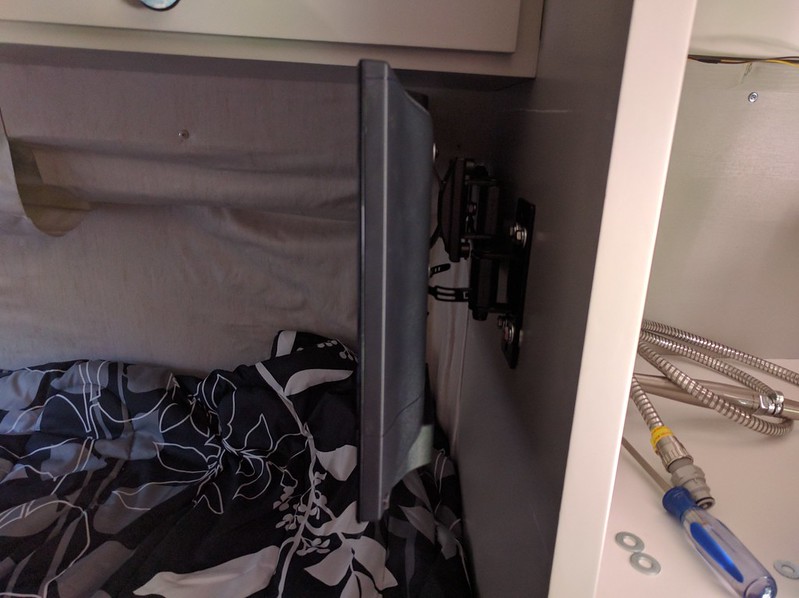

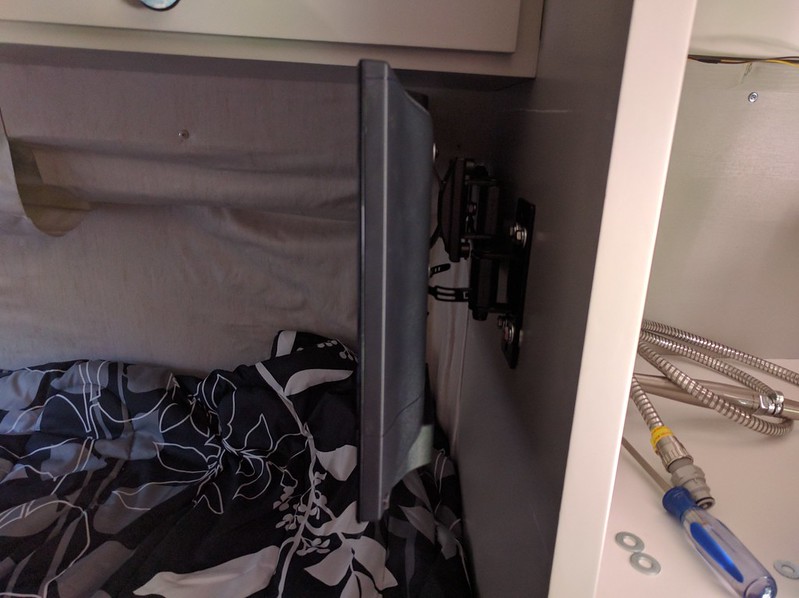

Jen has been working on installing a small TV for use in the sleeping area. It will be connected to a micro media PC which can also double as a windows workstation.

The pivot arm is poor quality, and the slop in the joints made the TV tilt. After some aggressive shimming and the application of some UHMW tape it sits fairly level.