http://amzn.to/1ODw8FS

http://amzn.to/1ODwe0a

http://amzn.to/1ODweNy

http://amzn.to/1ODwfkw

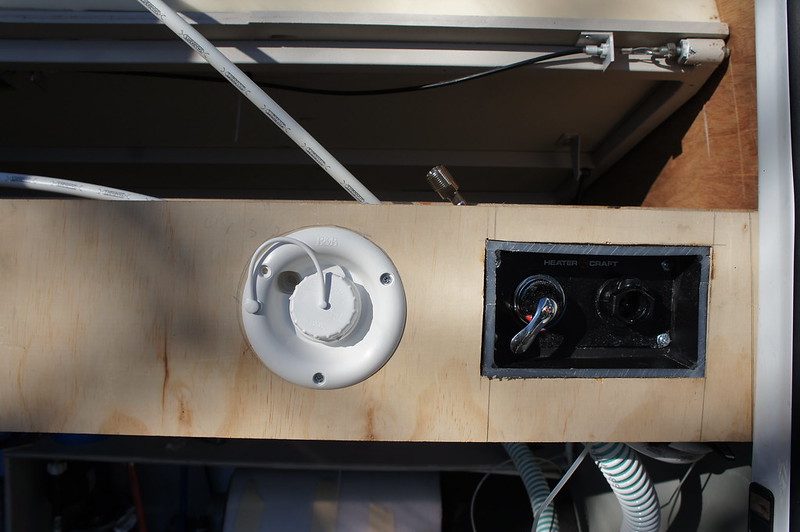

We are using a Blue Sea dimmer to control the lights. A really useful feature of this unit is the ability to connect multiple control switches in parallel.

http://amzn.to/1VxojB0

The welding on the bed supports has been completed and they have been painted. Rubber has been bonded to the bed frame to eliminate rattles.

The 2 mistake cabinets have been mounted over the bed. The lengths worked, so no additional modifications were necessary! (We have to get lucky sometime right?) Some photos show how I mount the cabinets to the van body. I used ¼-20 rivnuts and 90 degree brackets. When 2 cabinets meet they are connected with ¼-20 bolts and T-nuts.

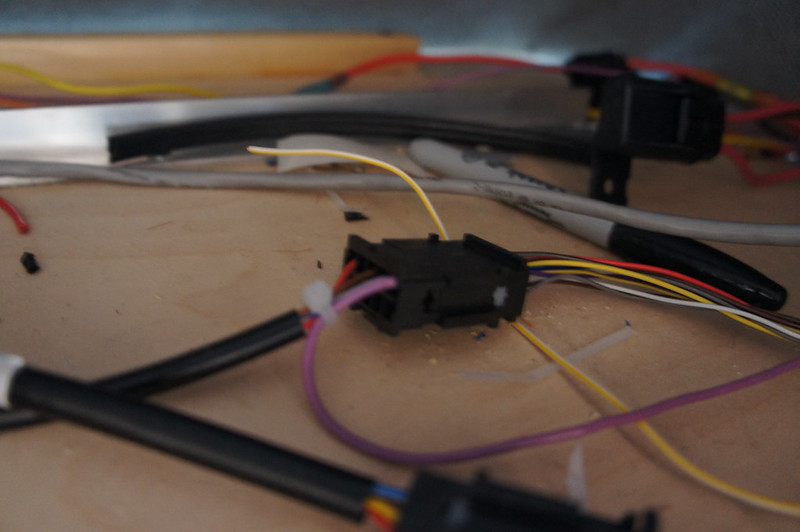

The wiring for accessory outlets and task lighting is coming slowly. There is substantial vibration proofing needed for plumbing and wire harnesses prior to closing up the cabinets.

Here are the USB and 12V outlets I am installing. I have read some reports that the USB outlet may not have the correct wiring pin out to enable high speed charging in some devices. I need to take one apart to confirm if the pin-out needs modified for optimal charging.

http://amzn.to/1VxpTTq

http://amzn.to/1Vxq1lU

Wall covering is on order, should be able to start covering wall panels when the weather warms. The cabinetry is mostly done at this point. All that is needed is hardware and painting.

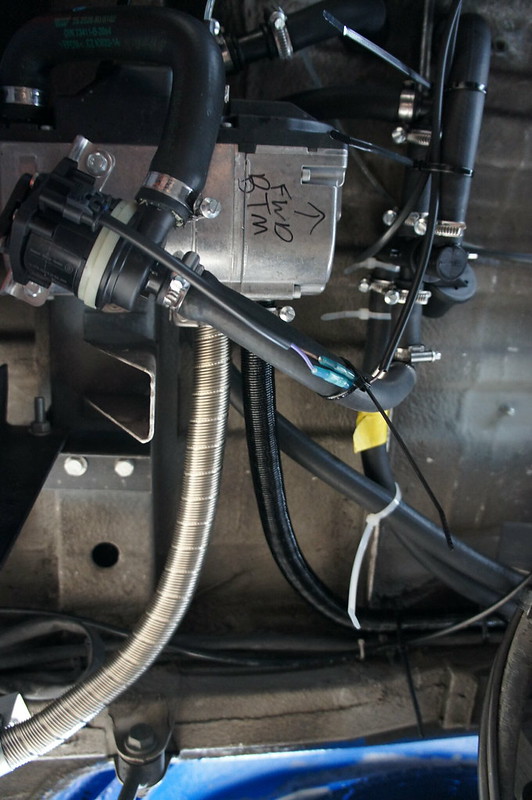

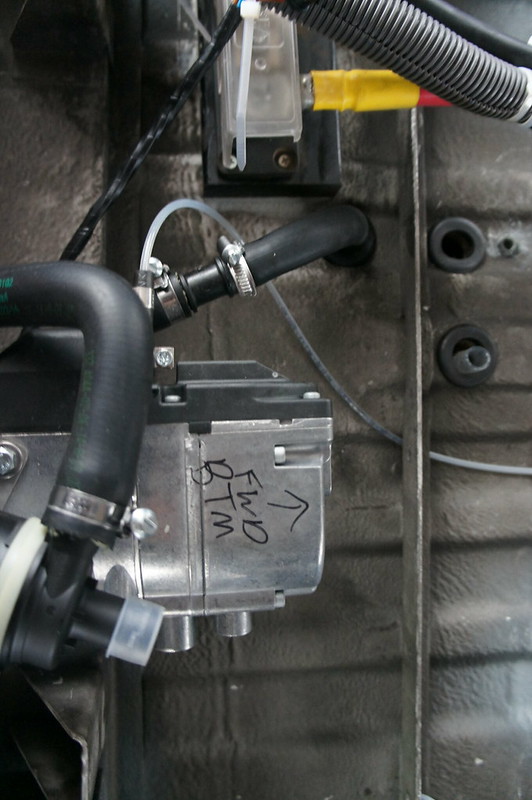

Edit: I checked the Espar Fuel Pickup today. NO LEAKS!!!!